EV BATTERIES

APPLICATIONS

Key Thermal Management Challenges:

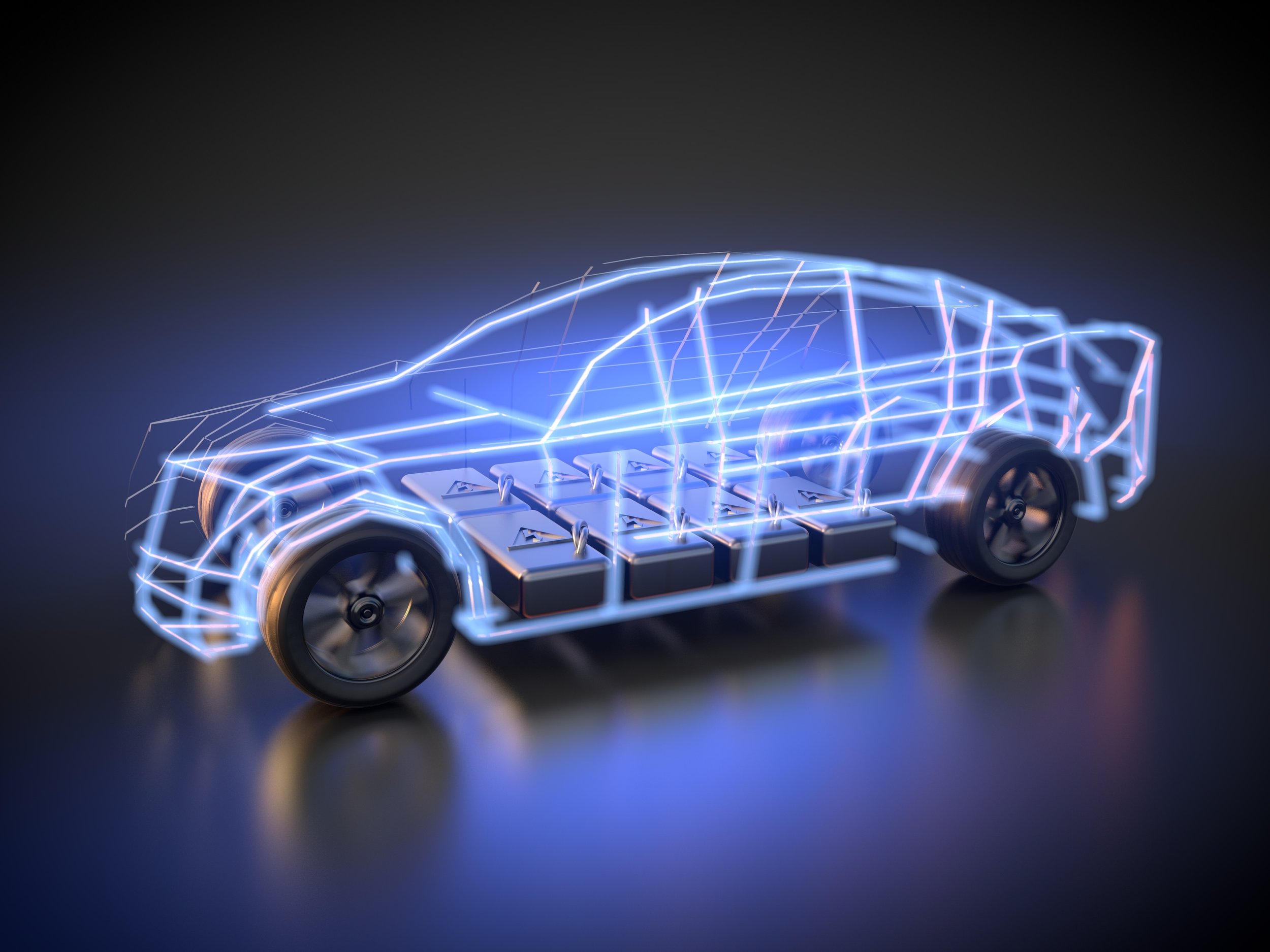

Modern electric vehicles (EVs) demand highly efficient battery thermal management systems (BTMS) to ensure safety, performance, and battery longevity. As EV platforms move toward faster charging, higher energy density, and compact battery pack designs, thermal control becomes a mission-critical requirement. This is where liquid-cooled cold plates play a central role—maintaining stable battery temperatures during charging, discharging, and rapid load cycles.

Whether in cell-to-pack (CTP) or module-based architectures, aluminum cold plates are embedded beneath or between cells to extract heat efficiently. Direct liquid contact through serpentine or impingement-style channels enables uniform cooling and minimizes temperature gradients across the pack. Poor cooling can lead to cell degradation, safety hazards, and reduced driving range.

High Heat Flux During Fast Charging: Temperature spikes must be managed without compromising pack structure or vehicle space.

Clogging & Flow Restrictions: Narrow channels in traditional cold plates can trap debris or precipitates, reducing long-term reliability.

Pressure Drop vs. Cooling Efficiency: EV manufacturers aim to minimize pump energy consumption while ensuring even fluid distribution.

Why ZeroKelvin Cold Plates Stand Out:

AI-driven topology optimization reduces pressure drop while maintaining thermal performance.

Unibody, leak-proof aluminum designs eliminate welds, joints, and failure points.

Compatible with dielectric or water-glycol fluids, enabling broad vehicle integration.

Scalable designs suited for pouch, cylindrical, or prismatic cell configurations.